Concrete is a mixture of different sizes of stones and gravel that typically consists of sand (fine aggregates) But now a days recycled materials are also being used that saves resources and are used as a substitute material.

Recent technology has shown Glass aggregates are more widely used and recommended by the manufacturers around the world.

Different glass options are available to be used as aggregates and substitutes other natural resources, It also gives a unique finish and glow to the surface and makes the interior or exterior appearance more appealing and modern.

Glass aggregates contributes more durability and provides more workability to the concrete finish. Furthermore, glass aggregates are cheaper options and more easily available. It offers many color options and sizes as per requirement.

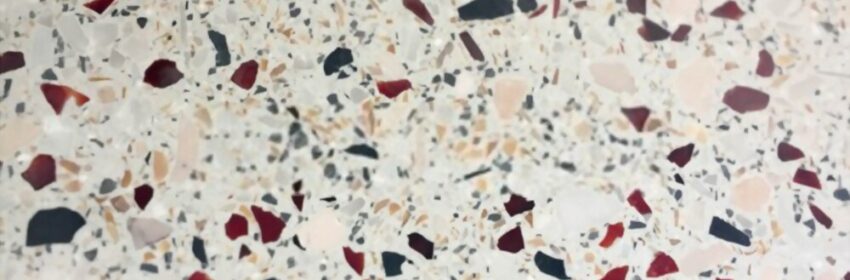

They add a highly polished shine and even offers unique colors to the floor finish. Glass aggregates are now more commonly used in applications such as flooring, surfaces and countertops as offer the best colors options to consider and recommend by the interior designers and architects worldwide.

Can Crushed Glass Be Used In Concrete?

Though using glass aggregates have no major issues in the quality and usability of concretes but it is important for manufacturers to use clean glass in concrete making in order to prevent issues related to an alkali-silica reaction between the glass aggregates and cement.

With the advancement in technology in modern era, glass aggregates that are collected from from post-industrial sources are crushed and well cleaned for use in indoor applications such as concrete floors, terrazzo and concrete countertops.

Not only glass aggregates offer multitude of color applications and sizes but it’s cheaper and adds value by contributing to the green environment by saving resources and more usage of recycled materials.

It Saves Resources And Reduces Landfill Spaces.

Its important to save environment as part of our civic duty and the use of recycled materials as an aggregate in concrete contributes in reducing the consumption of natural aggregate in large quantity. Since the usage of recycled materials in concrete can add more strength and durability, studies show that usage of recycled glass which is either partially or totally used as replacement for natural sand aggregate gives more strength as compared to the other types of recycled aggregates.

Since glass chips and mirror aggregates are recycled materials used in concrete, there is less extraction of natural minerals and resources and thereby saves energy and resources. It is the most important and essential factor of today’s construction landscape that the usage of recycled glass contributes to this healthy environment conservation.

Color And Sizes Of Glass Aggregates

The usage of glass aggregates is easy in concrete, considering two factors size and color of the aggregates.

Glass is graded by size. Glass aggregates are available in many sizes as they can be crushed to fine powder form or up to many inches as desired. They are quite easy to handle and commonly used in floorings, countertops, terrazzo etc. Contractors also use exposed aggregate techniques where the glass is broadcast across the surface and exposed as per desired design need.

Glass aggregates are available in several colors and gives an appealing look due to its gloss and shine. Other natural material like marble chips and gravel offer less color options comparatively. You can make your choice as several options are available from blue, red, brown, green, purple, black, yellow and more.

The contractor gets a free hand options to compose and can mix glass with concrete in any way they opt for. They can add more dark colors with a light matrix or just one color tone or even mix many different colors as desired.

Clear glass options are also available for more subtle look as it takes on the color of the matrix. Now one can have many choice of floorings and countertops to choose from.

Glass aggregates are the best replacement of sand and gravel in concrete For more appeal and unique finish and more colorful effects on terrazzo to a natural marble like finish or something that reflects like a mirror, glass aggregates are the best options in concretes.

Can Glass Aggregates Be Used in Outdoor Concrete Application?

There are many research conducted on glass aggregates usage in concrete. Some studies show that usage of glass aggregates for outdoor concrete applications results in alkali-silica reactions as they are more exposed to moisture.

The silica in the glass and the alkali in cement forms a gel that swells in the presence of moisture. This reaction can cause cracks to form. The question is, is there any ways to stop this reaction?

The answer is yes. A good sealer is being used to suppress the reaction (presuming one haven’t used too much of water in the mix) or met kaolin can be used to suppress the reaction or contractor can grind the glass finely to pass smaller screens.

Of course, keeping out moisture with a good sealer will also suppress the reaction.

Glass Aggregate Crushing

Today worldwide post-industrial and post-consumer recycled aggregates are being crushed, cleaned and processed and later properly packaged for contractors and builders to purchase for concrete or terrazzo applications. So If you want to produce concrete that truly shines and glows put some glass in the mix.

For concrete applications, Glass aggregates used in concrete applications are more commonly used in countertops, floors, walls, and other decorative designs. For any indoor environment where you desire to produce a beautiful, durable and low maintenance surface concretes and terrazzo floorings; usage of crushed glass aggregates mix is the best solution.

One more advantage of glass aggregate is that it can replace part of or all of the sand and gravel in concrete mix and thereby gives beautiful effects that range from colorful terrazzo to marble-like finishes or like natural granite or a surface that reflects like a mirror.

Glass aggregates at BSG GLass is typically graded by their sizes and colors. Besides high-tech techniques are used for grinding, polishing and other exposed aggregate techniques are carried out to reveal the glass.

From crushed clear glass chips to crushed colored glass chips BSG Glass produces all types of aggregates. Our glass aggregates are obtained from a variety of sources likely, crushed bottles and other glass material which are monitored and cleaned and sorted by size and color.

BSG Glass chips fits in well for every decorative concrete arena and mostly used in countertops. However also used in terrazzo floors, even walls and furniture tops or where any decorative concrete is found – indoors or outdoors both.