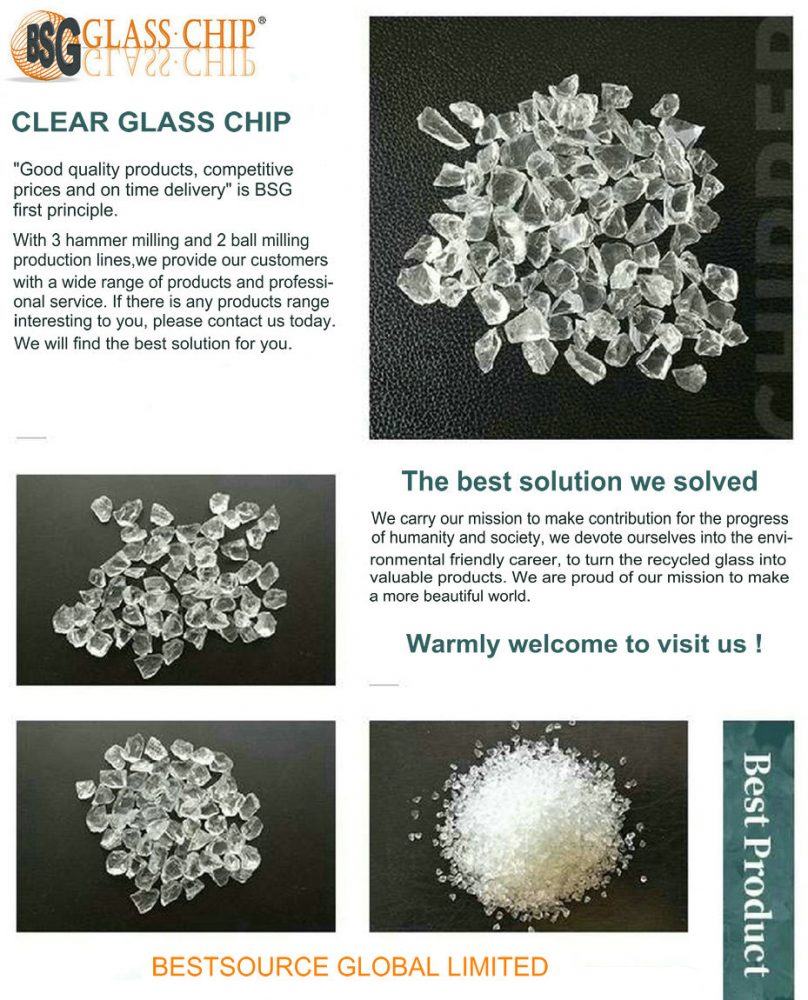

Crushed Clear Glass Chip is BSG main product. In nowadays, there are two main crushed glass chip production technologies. One is Hammer Milling System and the other one is Ball Milling System.

Hammer Milling system is a traditional technology to crush the glass, most of the glass particles produced are mainly in large granules. The Ball Milling system mainly focuses on small particle sizes chips. Due to Ball Milling glass chips’ round & smooth surface, it is helpful to consumpt less resin and make the slabs tronger construction during slabs production.

Since the glass raw materials are environmentally-friendly recycled, there are no natural impurities same as quartz sand, BSGglasschip® Crushed Clear Glass is a good material for quartz stone & engineering stone production.

So far, we already build up 4 Hammer Milling System and 3 Ball Milling System production lines whitch could provide more than 12,000 metric tons capacity monthly to our cusotmers from worldwide.

How we Do it

Our raw materials are from 100% recycled glass of glass production industry. Keeping the importance of environmental protection as key feature. Besides, it’s free from impurities and zero color difference in different batch shipments that you receive from BSGglasschip®.

Features

Usage

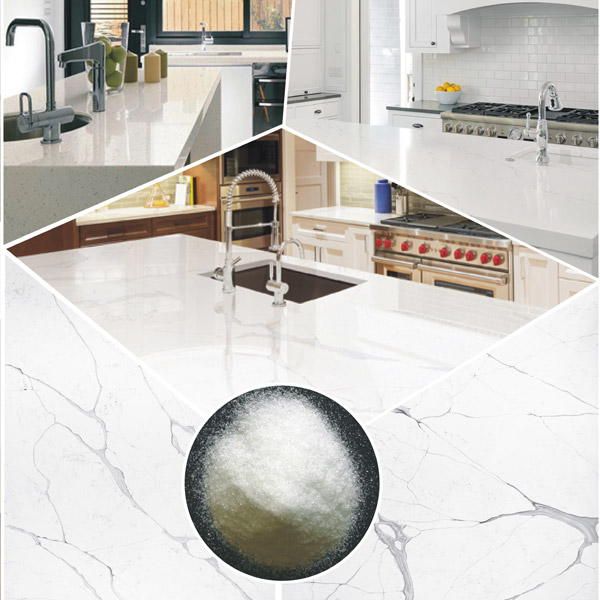

- Quartz stone, engineering stone and other man-made stone production.

- Glass Beads.

- Terrazzo, Concrete & Floor decoration.

- Other application.

Advantages

BSGglasschip® have advantages of smooth & round shape surface, with different kinds of sizes available. Quartz stone/Engeering stone slab produced with BSGglasschip® could be in higher glossy surface.

It is continuous raw material supply and environmental protection. Also, it is almost zero impurities and no color difference in different batch shipment. It can replace Transparent Quartz sand and Semi-Transparent Quartz sand, because its Transparent feature. It is perfect for use in Quartz stone, Engineering stone and other man-made stone production.

explore

Chips Types

Chips Sizes

0.065 – 0.125mm

0.125 – 0.2mm

0.2 – 0.4mm

0.065 – 0.125mm

0.4 – 0.7mm

0.7 – 1.2m

2 – 2.5mm

2.5 – 3.5mm

Other sizes available

Our Capabilities:

The factory total maximum capacity to produce clear glass chips is 12,000 metric tons per month. The cutting edge technology enables us to meet the demand and supply to offer our customers new-generation high-quality products at all times.

Order Note:

Minimum Order Qty: 1 Metric Ton/Size

Packing: 1 or 1.25 Metric Tons/Jumbo Bag, 20 Jumbo Bags/20’GP,

or small bag of 25KGS/Bag.

Other packing is available as per requirement

Very dry, clean and no impurity

explore

Applications in Quartz Stone

explore

Applications in Glass Beads

Usage:

They are widely used for producing kitchen countertops, terrazzo, flooring, quartz, stone, and decoration materials. These days the exterior counters and decorative floors concrete are embed with crushed clear glass to give it more enchanting and captivating appearance.

Features:

They have excellent texture, uniform particles, compact structure, high compressive strength, excellent wear resistance, strong corrosion- resistance, durability, and decorative properties.

Qualities:

They have excellent texture, uniform particles, compact structure, high compressive strength, excellent wear resistance, strong corrosion- resistance, durability, and decorative properties.

Our

Recent Blog Post

How Glass Powder Makes Ceramic Products Better

Ceramics are everywhere! We use them in tiles for our floors, dishes for our meals, and even in some high-tech gadgets. Glass powder is a special ingredient that makes ceramic products even better. Let’s find out how glass powder helps ceramics and why it’s so useful. What Is Glass Powder? Glass powder is made by […]

Read more

The Art of Using Crushed Mirror Glass in Mosaic Designs

Mosaic art has a timeless allure, captivating enthusiasts with its intricate patterns and vibrant colors. One particularly stunning element that can elevate mosaic designs is crushed mirror glass. The reflective properties of mirror glass add depth, dimension, and a touch of glamour to mosaic creations. In this article, we’ll delve into the art of using […]

Read more

Quartz Stone Manufacturing Process

The quartz stone manufacturing process begins with the selection of raw quartz materials. Since many years, natural stones such as granite and marble have always been used widely at both residential and commercial buildings for kitchens bathrooms, counters etc. What are the disadvantages of using Natural stone? They are less smooth as compare to quartz […]

Read more

Glass Beads Production Materials

There are many different materials that can be used to make glass beads. In this article, we will explore some of the most popular options so that you can make an informed decision about which one is right for your project. What are glass beads? Glass beads are often used in jewelry and other decorative […]

Read moreFAQs

where can i buy crushed glass for crafts

Bsgglasschip.com offers crushed glass for crafts at reasonable prices with 100% satisfaction guarantee ✔️Fast worldwide shipping! ✔️Frequent special offers and discounts.

where to buy bulk crushed glass?

Bsg glass chip provide bulk crushed glass chip and crushed copper glass chips with 100% satisfaction guarantee. You can achieve a dazzling finishing touch with the finely crushed shapes and translucent color.

Contact Us

REQUEST A QUOTE