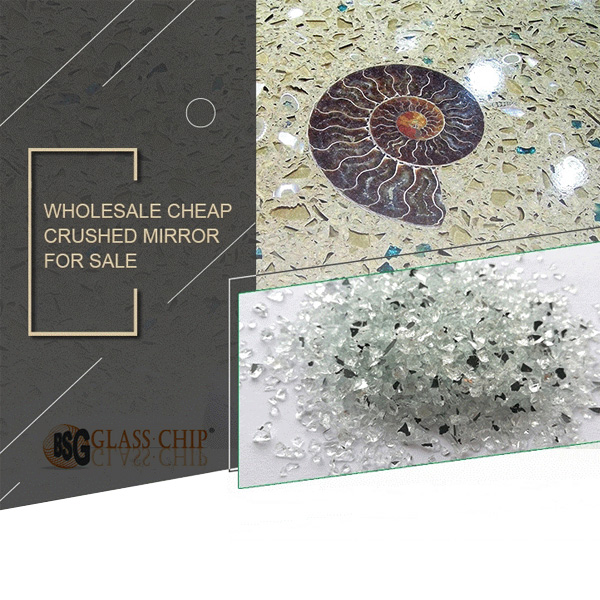

BSG produce Crushed mirror glass chips, include Double Sides Mirror Chip, White Backside Mirror Chip, Black backside Mirror Chip which can provide a very good reflective effect on the different colors series final product. Such as quartz stone, engineering stone, and other man-made stone products.

Quality:

BSGglasschip® believe in quality and trust, therefore our mirror glass chips are cleaned up carefully before crushing the raw material.

For a better quality mirror coating, we use high-tech crushing system to crush the raw material so as to keep the mirror percentage at a higher level during crushing. Customers use less mirror chips quantity in production with higher reflective result by using our BSG mirror chips.

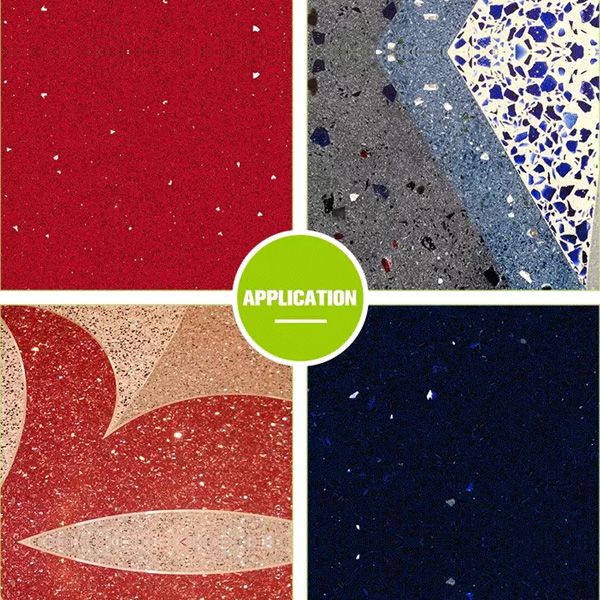

The different mirror glass chips have reflective quality which gives a stunning combination of different colors series quartz stone, engineering stone or other man-made stone and decoration field.

explore

Crushed Mirror Glass Chips Types

Crushed Mirror Glass Chips Sizes

0.1 - 0.6mm

0.6 - 1.2mm

1.2 - 2.5mm

1.0 - 3.0mm

2.5 - 4.0mm

3 - 6mm

4 - 6mm

Other sizes are available

Usage:

- Used in quartz stone, engineering stone production and displays areas to give a modern and sleek look.

- Crushed mirror glass chip looks absolutely amazing in polished concrete or docoration fields as its gives a sparkling reflection effect and looks amazing in different atmosphere.

Advantages:

- Each application is 100% unique.

- More open space feel, as natural light reflects off the mirror glass and is then projected around the area.

- One can personalize the Mirror Glass Chip is through incorporating another product type such as colored glass chip or special products.

Order Note:

We have size range of crushed mirror glass chip, which are available in different packaging to suit a wide variety of applications.

Minimum Order Qty: 1 Metric Ton/Size, 1 or 1.25 Metric Tons/Jumbo Bag, 20 Jumbo Bags/20’GP, or small bag of 25KGS/Bag.

Other packing is available as per requirement

Very dry, clean and no impurity

Capacity: 5,000 Metric tons per month

Mirror Chips Applications

Our

Recent Blog Post

How Glass Powder Makes Ceramic Products Better

Ceramics are everywhere! We use them in tiles for our floors, dishes for our meals, and even in some high-tech gadgets. Glass powder is a special ingredient that makes ceramic products even better. Let’s find out how glass powder helps ceramics and why it’s so useful. What Is Glass Powder? Glass powder is made by […]

Read more

The Art of Using Crushed Mirror Glass in Mosaic Designs

Mosaic art has a timeless allure, captivating enthusiasts with its intricate patterns and vibrant colors. One particularly stunning element that can elevate mosaic designs is crushed mirror glass. The reflective properties of mirror glass add depth, dimension, and a touch of glamour to mosaic creations. In this article, we’ll delve into the art of using […]

Read more

Quartz Stone Manufacturing Process

The quartz stone manufacturing process begins with the selection of raw quartz materials. Since many years, natural stones such as granite and marble have always been used widely at both residential and commercial buildings for kitchens bathrooms, counters etc. What are the disadvantages of using Natural stone? They are less smooth as compare to quartz […]

Read more

Glass Beads Production Materials

There are many different materials that can be used to make glass beads. In this article, we will explore some of the most popular options so that you can make an informed decision about which one is right for your project. What are glass beads? Glass beads are often used in jewelry and other decorative […]

Read moreContact Us

REQUEST A QUOTE